Showing 1–24 of 33 resultsSorted by latest

The use of high human resources within the construction sector has led to the development of a large number of robotic systems, focused on automating multiple tasks that are part of construction processes. Both in housing and infrastructure works.

In some cases, these are robots specifically built to solve a specific process.The precision and productivity provided by these new tools, undoubtedly help to solve the needs of any building or construction. Used industrial robots can be used to carry out a specific task; assembling the components floor by floor and raising the level as you gain height in the construction of the structure.

It is estimated that, in a short period of time, no more than five years, a percentage of around 20% of the work done in the construction sector will be done by second-hand industrial robots. Therefore, the opportunity is already beginning to recognize the rapid technological change and begin to establish a transformation strategy towards second-hand industrial robotics. To date

Located on a mobile platform, the robotic system can locate bricks even six times faster than a worker, providing a high reduction in costs and time. This equipment has a robotic arm, a pump to store the cement and a warehouse where the bricks are deposited.

These new tools make work in construction easier; they provide greater precision, productivity and safety. They cover all levels, from the assembly of parts to the inspection of a finish.

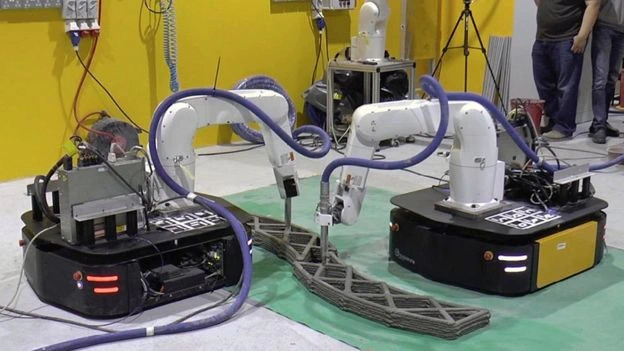

We are still in the early stages. Right now, preowned industrial robots are being tasked with tasks such as demolition, masonry, drilling, 3D printing and even welding rebar.

Drones are also being used more widely to explore hard-to-reach areas and obtain information that would otherwise be very difficult. Their high capacity to cover a wide perimeter in a short space of time and capture images with high precision is a huge step forward in the development of inspection processes.

A second-hand industrial robot system modifies the environment and the functions to be performed by the workers. The role of robotics in construction will be, on the one hand, to replace the worker in carrying out dangerous tasks, complementing his work by using a second-hand industrial robot in different processes, providing more strength, resistance and precision, under the control and planning of the worker. In this way, safer work is achieved and productivity and process quality are increased.

The increased use of modern construction methods has led to the possibility of external manufacturing. This involves building parts or modules in a controlled factory environment away from the construction site and then transporting them to the site for final assembly.

In this way, it is possible to carry out such surprisingly rapid implementation projects, such as that of the Wuhan hospitals in China during the current Covid-19 or coronavirus pandemic.

Once again, the fear of change generates the eternal doubt: Will there come a time when robots take away our work?

Robots are more efficient; they work faster and in the medium term they are cheaper. The fear of being replaced by machines comes from way back, and there are two schools of thought: one believes that many of today's jobs will be done by a machine, while the other believes that using robots will help create more jobs.

The logical thing to do is to think that if a process can be automated, it will be done by an industrial robot and it will certainly be used.